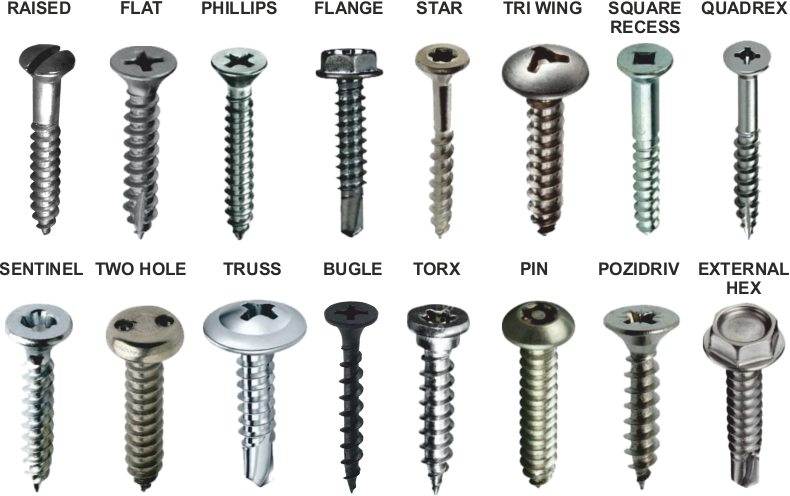

Types of Screws

When it comes to screws, there are a lot of different types. There are truss head screws, pan head screws, flat head screw, and more.

One type of screw that is a bit of a mystery is the monster head screw. It seems like a pretty standard fastener, but it has a weird shape.

Hexalobular/6lobe socket type screws

Hexalobular/6lobe socket type screws host a six-lobe recess and are driven using a 6-lobe wrench or insert bit which improves their efficiency when compared to slotted screws and hex drive screws. They are usually supplied in grade 8.8 or 12.9 Steel and A2 Stainless Steel as standard but other materials such as Brass, Aluminium and Titanium can also be supplied on request.

Hexalobular socket head screw drives are designed to permit increased torque transfer from the driver to the bit, reducing radial forces and extending tool life by avoiding camout problems. They also have vertical sidewalls which reduces pressure required to retain the screwdriver in the fastener.

These screws are available in UNC & metric thread types and various lengths. They are suitable for a range of applications including garage door, HVAC, automotive, heavy equipment and lawn/garden. They are reusable, heat, tamper and corrosion resistant and feature captive O-rings. They are lean manufacturing capable, RoHS compliant and meet ANSI, ASTM, ASME and CSA standards.

M3 – M6

The M3 – M6 range is an excellent choice for your next mobile project. These hexagonal socket head screws come in a variety of sizes and materials to suit your needs. They have a number of nifty little features that make them stand out from the rest. They have a hefty price tag but are well worth the investment. They are also very easy to install and come with a nice looking packaging.

There are a few things to consider when picking your next monster head screw. First and foremost, you need to figure out what size you need before buying. This will ensure that you get the right size and don’t waste your hard earned cash on something that won’t fit. Then, you’ll want to pick a quality manufacturer with a great return policy. Lastly, you need to look at the warranty and delivery times before purchasing any new hardware. The last thing you need is a faulty product that won’t get you anywhere.

M8 – M10

The M8 – M10 monster head screw is one of the most common screws on the market. They are used for a wide range of applications including caravans, motorhomes, boats, sign mounting/fixing, DIY uses and around the home.

The metric threads on these screws are a bit on the large side (the size of the bolt shank) but they are still plenty strong enough to support weighty objects like tools and hardware. These types of screws are available in a variety of materials, including steel, brass and aluminium.

When choosing the best type of fastener for your project, it’s important to take note of the standards used in each country to make sure you get a screw that will perform as intended. These include the ISO, JIS and DIN standards. The metric system is the world’s most widely used standard and is also the most likely to be adopted globally in the future. This is because the metric system uses the same unit of measure for all measurements, resulting in a very similar set of rules for measurement and comparison.

M12 – M14

The M12 – M14 monster head screws are the largest of the metric hexagon socket head cap screw sizes. The screw is usually drilled on both sides of the socket. The drilled holes are typically spaced 180 degrees apart.

The screws are made from a variety of metals, including alloyed copper and brass. These materials are hard and light, corrosion resistant, and are easy to manufacture.

These screws are available in a number of different finishes, such as black oxide and chrome coating. These coatings enhance the strength and durability of the screw, while not enlarging its dimensions.

These threads are also available in fine and course pitch configurations, allowing users to choose the best option for their application. Many of these fasteners are designed to break away when sufficient torque is applied to the head, which prevents tampering and allows for an easier inspection of the joint. This makes them ideal for applications such as vehicle steering columns and other similar hardware.