The Versatility of a Servo Press

A servo press can help manufacturers reduce costs and increase productivity. This is due to the fact that servo presses have 30 to 80 percent more available energy than mechanical presses with similar tonnage.

Servo press are also more efficient than conventional mechanical presses because they use less energy to produce a part. Hence, the demand for servo presses is increasing among manufacturers.

Cost-Effectiveness

Servo presses are a cost-effective solution for many industries. Compared with hydraulic presses, they are more energy efficient and require less floor space for storage of hydraulic fluid. Servo-driven crank presses also cost much less than their mechanical counterparts because they do not use a flywheel or clutch.

The cost-effectiveness of servo presses is further increased by their versatility. They can be used for a variety of applications, from stamping parts to delicate assembly operations.

In automotive manufacturing, for example, servo press applications can be as simple as attaching a door hinge to a door, or as complex as assembling a dashboard. The ability to adjust a servo press’s force and position to ensure precision results in both faster production and greater quality of finished products.

Using computer software, servo press operators can more flexibly control their presses’ speeds and positions. This allows shops to apply high forming loads early in the stamping process and maximize productivity while ensuring dimensional accuracy.

A servo press’s high accuracy and inherent feedback loop enable it to monitor the forces that are applied. This is especially helpful in a complex assembly, such as pressing a hinge to a door.

In addition to its flexibility, a servo press has several other benefits that make it more efficient and cost-effective than traditional mechanical or hydraulic presses. These include:

* Energy Efficiency – Unlike mechanical presses with a flywheel and clutch, which are continually rotating, servo motors only require power when the press is moving. As a result, servo motors are more energy efficient and use 10 to 20 percent less energy than their mechanical counterparts.

** Adaptability – Servo presses can be easily configured for any type of die functions and forming processes. They are available with various torque and power capacities from 1,000 to 2,000 kN.

Servo-driven presses are especially useful for processing advanced high strength steel (AHSS) grades because they are more energy efficient than other presses, while still maintaining dimensional precision. The ability to control a servo-driven press’s speed and position can allow stampers to apply higher forming loads earlier in the process, which can help reduce part weight.

High Precision

Unlike hydraulic presses, which use counter-parts to control force, servo presses utilize high-torque electric actuators. This makes them more flexible, precise and reliable than their hydraulic counterparts.

The closed-loop feedback system of a servo press provides full control over the pressing action and cycle time. This ability makes servo presses ideal for forming applications that require high torque, speed and slide motion.

A servo press can be used to form products in a number of different ways, including pressing-fitting, riveting, sealing, bending, drawing and forming. It can also be used to perform secondary processes such as surface finishing and cutting.

When the slide velocity is controlled to match material flow, a servo press can be used to produce fineblanking in a shallow-drawing application. This eliminates the need for secondary machining and ensures consistent quality after thousands of strokes.

In addition, servo presses can be used to achieve higher productivity because they can shorten the forming cycle. This is achieved by combining a partial short stroke around bottom dead center with a high-speed return motion.

This method is particularly useful for high-precision stamping applications, which often involve a combination of deep and shallow-drawing operations. Moreover, it is especially useful for thin-gauge material.

Additionally, a servo press can be easily integrated into a manufacturing process. This means that a single machine can be used to complete multiple processes, which saves time and reduces production costs.

Compared to hydraulic presses, servo presses have a much smaller footprint and can be installed in confined spaces. In addition, they have lower noise levels.

A servo press is also more versatile than traditional mechanical or hydraulic presses, as it can perform tasks that require different torque, speed and slide motion. This makes them suitable for a variety of applications, from stamping to welding and bending.

A servo press has the ability to control a wide range of parameters, including the ram pressure, travel and positioning time, load and force. This gives manufacturers the ability to adjust these factors to suit their individual needs. In addition, a servo press can be more accurate than a mechanical press because of the closed-loop feedback system.

High Force

Servo presses can produce tons of force, which is ideal for applications where metal must be pierced through to form parts. They are also more energy-efficient than hydraulic presses and less prone to contamination.

A servo press has the ability to change its velocity throughout its stroke, which can help reduce material resistance and speed up production. It can also dwell anywhere within its stroke, allowing different aspects of a part to be formed.

Some servo presses can even operate at lower rpm, which is especially beneficial for stamping applications. The servo press can even store energy during deceleration, which can be used during short energy peak demands of the next stroke.

This feature allows for a high forming limit and better accuracy. Additionally, it allows the servo press to operate at higher speeds than hydraulic presses.

Another benefit of servo presses is that they can be customized to suit specific production needs. They can be configured with a wide variety of features, including multiple axes, which can be synchronized to ensure smooth operation.

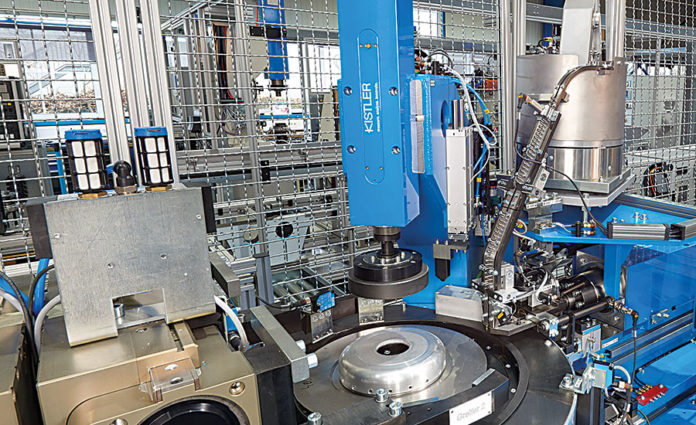

For example, a machine manufacturer from Furtwangen in Germany needed a single press that could crimp both very fine and massive components to form one subassembly. It chose IEF-Werner GmbH’s aiPRESS servo press, which has a pressing force of 12 kilonewtons and is capable of meeting the customer’s requirements for quality and efficiency.

The aiPRESS servo press was able to achieve the required precision without the need for a separate high-precision system, which saved the company money on investment costs. Moreover, it was possible to reconfigure the press’s force ranges to meet future demands.

In addition to providing superior force and precision, servo presses are also optimal for push-motion operations. This function keeps the rod and slider pushed to the workpiece, which can be useful in various work processes, such as press fitting and caulking.

Besides being very efficient, servo presses are environmentally friendly and can be used in a variety of environments. They can be installed in a clean room and are quieter to operate than hydraulic presses, which are more susceptible to contaminants.

Versatility

The versatility of a servo press can be hard to pin down, but it is an important part of its appeal. Servo presses are the best of both worlds, offering the speed and power of hydraulic presses with the flexibility of mechanical presses.

Servo press users can set the slide to move at different speeds throughout the stroke, which allows for better part ejection, material feed and tool close than either a traditional or hydraulic press. This also ensures high productivity and quality.

For example, a manufacturer using a Komatsu gap-frame servo press has been able to increase the production rate for a specific job from 40 SPM to 75, stamping materials like 1050 spring steel as well as higher-carbon steels like 1095.

In addition, the servo press can be programmed to do progressive forming under one die. This is especially useful in applications that require titanium eyeglass frames, which are difficult to form because of their springback characteristics.

Another application that has been optimized by a servo press is the warm forging of stainless and mild steel components. Traditionally, this type of forging was performed as a two-step process: cold forging and then hot forging. However, the servo press is now the preferred way to perform warm forging because it reduces the length of the forging cycle while producing components of superior quality.

Additionally, the servo press is able to reduce energy use by allowing it to run at lower speeds during the forging cycle. This is a great benefit for many manufacturers, as it can save them money on electricity and the associated maintenance costs.

While servo presses are a new technology, they are gaining acceptance in many industries and are growing in popularity with metal stampers. In fact, many automotive metal stampers are slowly transitioning from mechanical presses to servo-driven presses, according to industry sources.

Beckwood offers a line of c-frame and 4-post servo-electric presses with standard models ranging from 1,000 lbf to 100,000 lbf (0.5 to 50 tons). These press systems provide a cost-effective alternative to hydraulic systems and offer force and positional feedback at a rate of 1 sample per millisecond. In addition, Beckwood offers optional features such as a heated platen and safety features that will improve the functionality of your press.