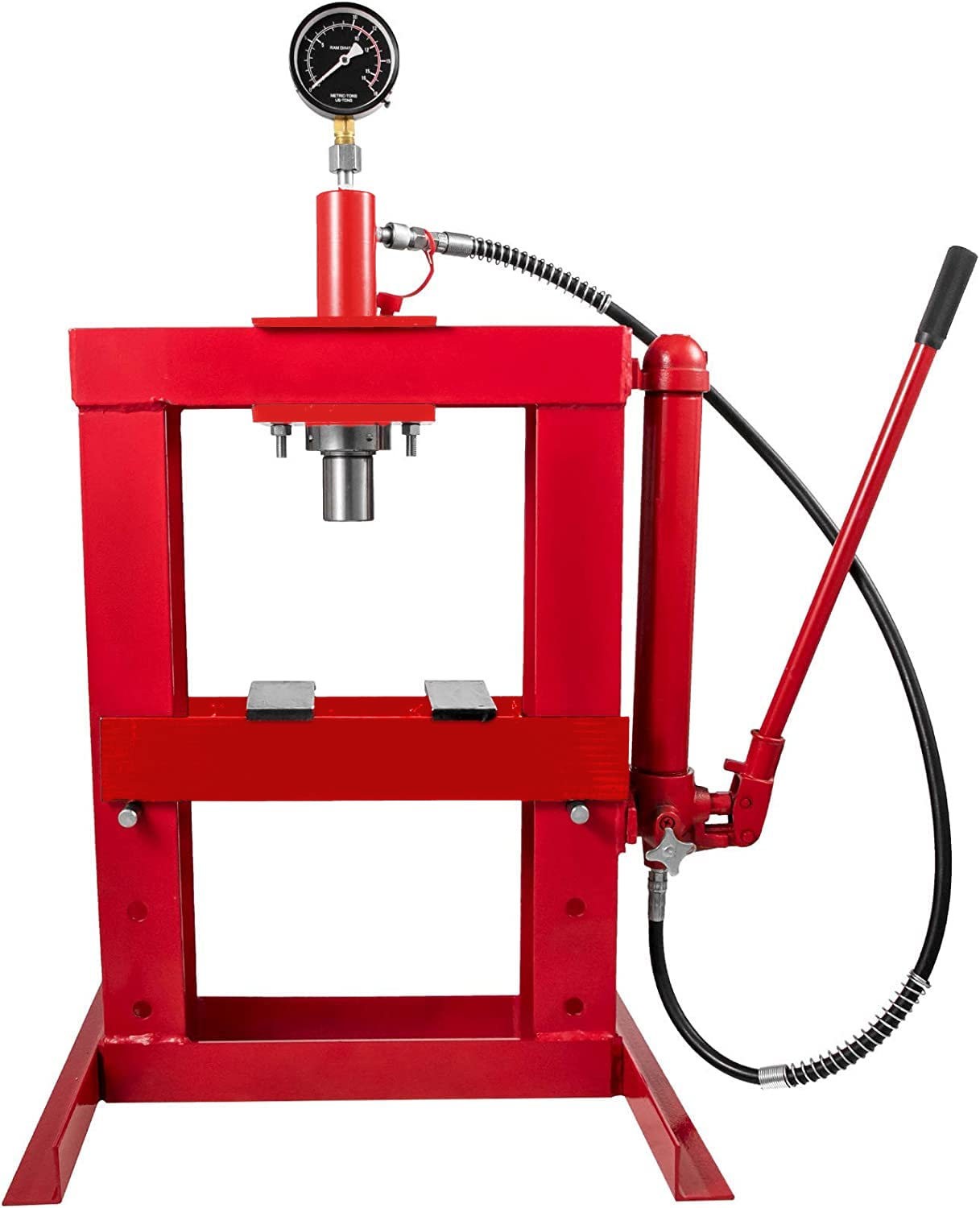

Hydraulic Press

A hydraulic press is a type of machine that uses Pascal’s law to generate a large amount of force. It consists of two cylinders, one smaller slave cylinder and a larger master cylinder.

The pressure inside the small cylinder creates a force that is transferred to the larger cylinder through sealing liquid. This force is then applied to the workpiece to be pressed.

Industrial Uses

Hydraulic presses are found in pretty much every industry where large-scale production takes place. They are used for forming metals in car manufacturing, making appliances and building aircraft, among others.

The hydraulic press is a simple machine that uses a cylinder and pump to generate a compressive force. It is also known as a Bramah press after the inventor, Joseph Bramah.

They have many industrial uses, including thinning glass, forming powders and tablets for medical purposes, and forging blades for swords. These presses can be purchased in a variety of sizes and capacities to fit any application.

Unlike mechanical presses, which only develop full force at the bottom of their stroke, a hydraulic press is capable of producing full pressure throughout its entire stroke. This is especially important in the case of a press that has to create an accurate, repeatable shape.

The hydraulic press can also be used to compress specialty waste products, such as an oil filter, to make them easier to transport and dispose of. This makes it possible to recycle the material, which is good for the environment and economy.

Agriculture

A hydraulic press is a device that uses Pascal’s Principle to create a large amount of force. It consists of two cylinders, one containing the ram and the other containing the plunger.

The ram presses the liquid between the two cylinders, causing it to force out through the plunger. The press is used in a variety of industries, including agricultural.

Agriculture is the process of redirecting nature’s natural flow of food to produce crops and livestock for human consumption. It also involves a number of other activities, such as forestry and fishing.

Hydraulic equipment makes farming and other agricultural processes faster and more efficient, reducing labor costs and helping farmers increase productivity. It is a key factor in the development of the industry and a driving force behind the transformation of agricultural production.

A strong and sustainable agricultural sector can create jobs, improve economic development and raise incomes in countries. It can also reduce environmental impacts and promote sound farm management practices that boost soil fertility.

Powder Manufacturing

A hydraulic press is used in a wide variety of powder manufacturing processes. It compresses powdered materials into various shapes and designs, allowing for a greater variety of products.

One of the most common uses for a hydraulic press is to produce metal matrix composites (MMCs) by combining powdered metal with a ceramic or polymer material. The resulting composite materials are strong and lightweight, making them ideal for a variety of applications.

Another common use for a hydraulic press is to prepare samples for scientific research. For example, KBr (potassium bromide) pellets are created by a hydraulic press for FTIR (Fourier transform infrared spectroscopy) analysis.

When using a hydraulic press, be aware that it can produce extreme force which could cause parts to shatter and fly like mini bullets. This is why it is important to take all precautions to ensure safety and prevent accidents.

Concrete

A hydraulic press uses the principle of Pascal’s law to apply pressure on a fluid. This allows the press to produce an incredible amount of force on a small area.

Hydraulic presses also use the same principles to compress concrete. They are a key part of the concrete wet pressing process that produces high-quality paving slabs and kerbstones.

Using the principles of hydraulics, a concrete wet press combines a slurry of wet concrete with an aggregate/cement ratio that is between 5:1 and 7:1, applying a press to a mould. Water is then filtered either side of the concrete to remove excess water and achieve a near-optimum water/cement ratio before it is compacted.

Hydraulic presses are useful for many different industries, from auto body shops to the military. They can be used to straighten bent parts and press out bearings, making repair jobs faster and easier.