Explosion Proof Valve Actuator

The straight shooters of the actuator world, these guys convert electrical energy into linear motion. They’re the James Bond of industrial controls, with built-in fail-safe mechanisms that revert to a safe position in case of malfunction.

ATEX certified, these electric actuators can be used in potentially explosive environments. They include quarter turn rotary ‘Max’ actuators and linear ‘Run’ actuators for ball, butterfly, plug valves and multileaf dampers.

Pneumatic Actuator

Using compressed air as their power source, pneumatic actuators work with a solenoid valve (also known as a pilot valve) to open or close your valve. A command from an electrical actuator controller is converted into a pneumatic signal that actuates the valve.

Unlike electric actuators, pneumatic actuators can offer high amounts of force for your application without being too big or too small. They are also more durable than many electric units.

Pneumatic actuators are commonly used in applications requiring high amounts of speed or thrust. They are capable of starting and stopping quickly to meet demands without sacrificing positioning accuracy.

For applications that may not have access to compressed air, explosion proof electric actuators are an excellent choice. These units reset to a fail-safe position during a power outage. They also come with a variety of performance metrics such as SIL 3, CE Certification, and IP68 weatherproofing.

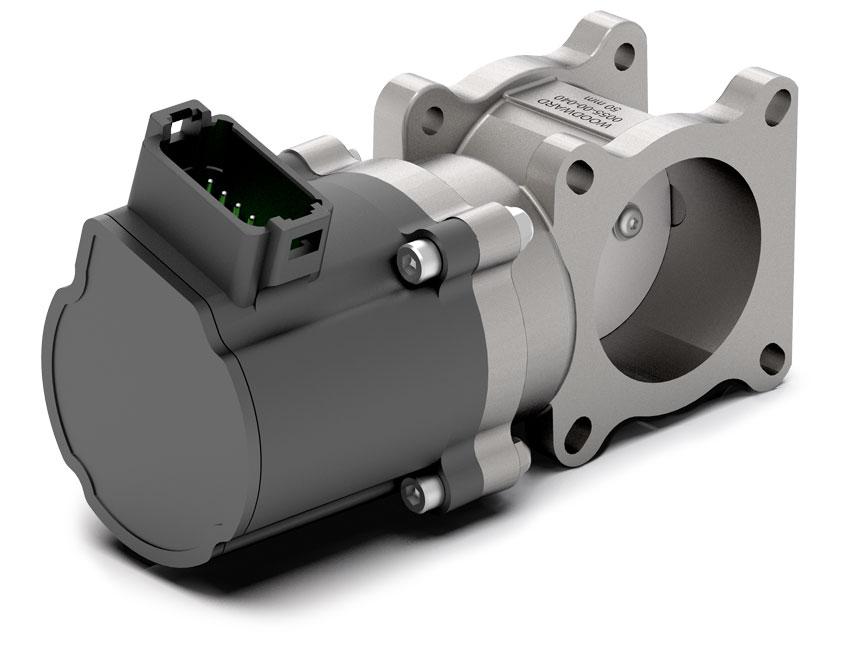

Electrical Actuator

An electrical actuator converts the input power signal into linear motion. This type of actuator is commonly used in flammable and explosive environments. It is easy to install and has many control options. It also features a visual valve position indicator and manual override. It is available in a wide variety of sizes and styles based on the application.

There are several performance metrics to consider when choosing an actuator, including torque, speed, and durability. These factors determine how well the actuator performs in different conditions and environments. An electrical actuator is a great choice for applications where space is limited and high reliability is required.

In addition, an electrical actuator is the best choice when it comes to energy efficiency. It uses less energy than a pneumatic actuator and offers a more precise movement. It is also easy to mount, making it a great choice for tight spaces. Integrated fail-safe features allow the actuator to shift to a safe position in the event of an error.

Hydraulic Actuator

If compressed air is unavailable or a harsh environment limits washdown and sealing options, then an electric linear actuator may be the best option. These actuators come in a variety of configurations that create powerful and reliable linear motion. They are self-contained with motor, pump and double-acting hydraulically operated piston within a weatherproof or explosion proof enclosure.

They are rugged and suited for high force applications producing thrust 25 times greater than a pneumatic cylinder of the same size. They can also operate at higher pressures.

They follow a demand signal from the controller instantly, without dead time or position overshoot. They can be used with the same solenoid-valve bodies as pneumatic actuators without the risk of process fluid seal leakage and the associated safety issues. This saves money on valve inventories for both hazardous and non-hazardous applications. They are also compatible with a wide range of control accessories. This includes limit switches and manual override handles that are easy to use in hazardous environments.

Group 57 Actuator

The Group 57 actuator is a DC powered electric actuator designed to meet the requirements of remote applications such as well heads and pipeline applications. They are explosion proof and reset to a fail safe position during power failures.

They can be factory-mounted to Hoke Selectomite 3-way ball, butterfly and plug valves for a pre-engineered assembly that saves installation time. They are available in four different models: on/off, modulating, and modulating failsafe. All are UL and CSA certified and are supplied with two auxiliary dry contact position switches to confirm valve position. They also come with a removable manual override for use without removing the actuator from the valve.

They are easy to install using standard ISO 5211 multi-flange mounting, double square drive, and a weatherproof enclosure. They can be used to automate quarter turn ball valves, butterfly valves, plug valves and dampers. The WE Series is CSA approved and the XE series is ATEX certified Ex d IIB T4 Gb / IP67.Explosion Proof Valve Actuator