Heat Sink Paste

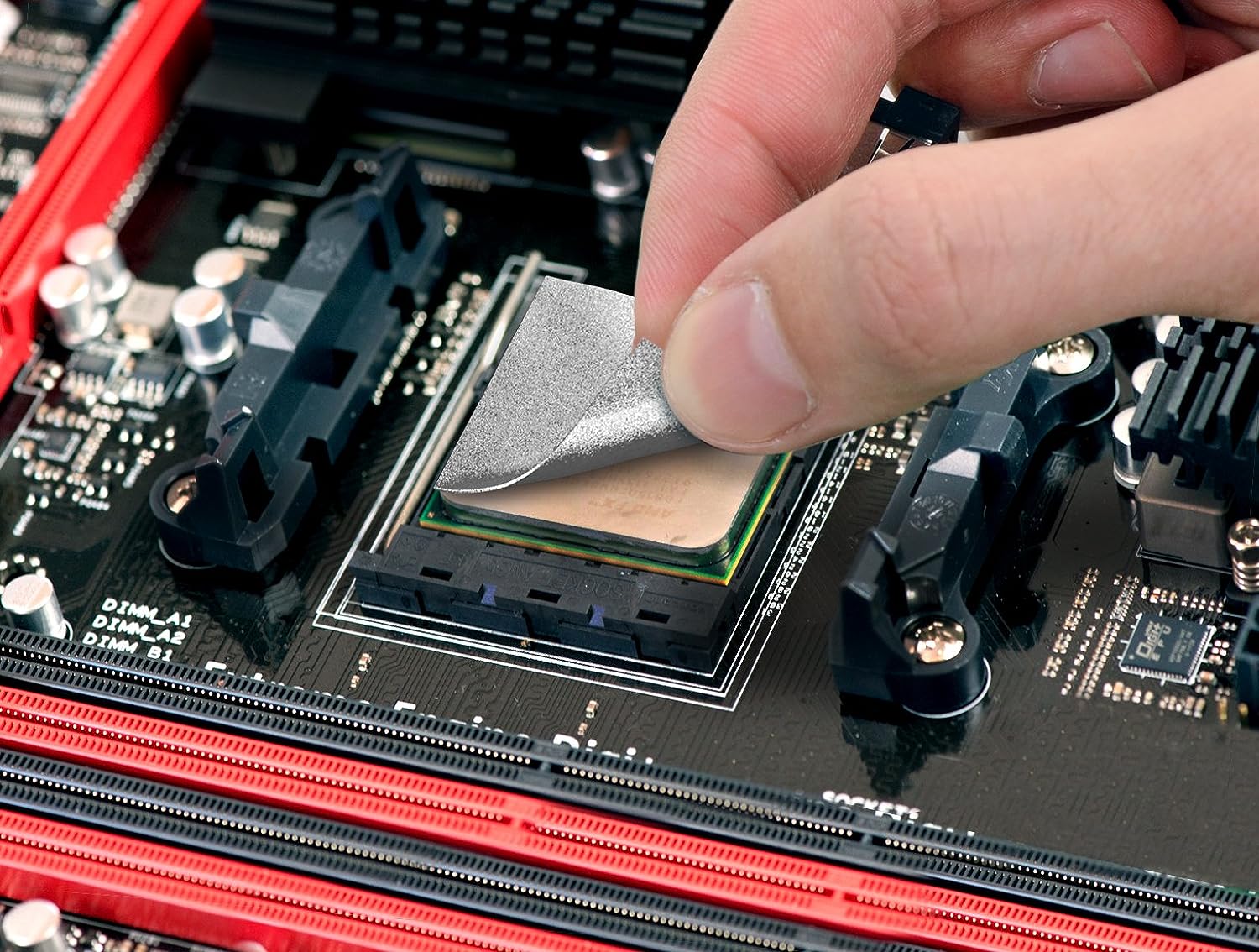

While the surfaces of a microprocessor and its heat sink may appear smooth, microscopic roughness and air gaps exist that act as an insulator, hindering efficient heat transfer. Thermal paste fills in these gaps, increasing surface contact and improving thermal conductivity.

The most effective (and expensive) pastes contain liquid metal, typically a variation of the alloy gallium. However, these compounds are electrically conductive and capacitive, posing risks of malfunction if accidentally spilled onto circuitry.

Metal Compounds

Thermal paste is a dense compound material used to improve heat transfer between an integrated computer chip (such as the CPU) and a metal heat sink. The best thermal compounds have high thermal conductivity to effectively lead the heat away from the processor and dissipate it into the surrounding air, which helps ensure a cool and stable operation. The base of most thermal paste is a polymer, which offers good adhesion and stability, while the filler is what provides the desired thermal conductivity. The most common fillers are boron nitride, aluminum nitride, zinc oxide and silver.

A metal-based thermal paste uses copper or silver particles suspended in a ceramic and silicone medium to provide better heat transfer than traditional pastes. They often have a conductivity of 3 to 8 W/mK or more. The metal particles can be made to a variety of sizes, which allows the manufacturer to control the flow of heat through the system. This type of thermal compound is often the most expensive and requires careful application to avoid short circuits in the electrical pathways.

Because two flat surfaces (such as a CPU and a metal heat sink) never join together perfectly, there are tiny spaces that trap air between them. This air is a bad conductor of heat and hinders the efficiency of a CPU’s cooling system. Heat sink paste is designed to fill these micro imperfections and eliminate air gaps to maximize the performance of a CPU’s cooling system.

Some of the highest performing thermal pastes, like the Phobya Liquid Metal Compound LM, are made almost entirely from liquid metal, usually a variation on the alloy gallium. These can have very high thermal conductivities, up to 13 W/(m*K), but are more difficult to apply evenly and may cause problems if spilled on electrical pathways. They also contain gallium, which is corrosive to aluminum, so they cannot be used on aluminium heat sinks.

Traditional Pastes

Thermal paste is a chemically constructed mixture used to allow for heat transfer between components. It consists of two main components, a polymer base and a thermally conductive filler. The polymer base is typically some form of liquid polymer such as urethanes, acrylates, silicones or epoxy resins. The filler is often made of a metal or ceramic particles suspended within the polymer matrix. The metal or ceramic provides the thermal conductivity. Other common fillers include boron nitride, aluminum nitride, alumina, zinc oxide and silicon dioxide. The polymer base helps to bond the filler to the component surface and provides a stable interface.

Silicone based thermal pastes have historically been the most popular type of thermal paste due to their low cost and ease of application. They offer high adhesion and stability, but their thermal conductivity is lower than metal-based pastes. Silicone based thermal pastes also have the potential to migrate into unintended areas due to capillary flow, leading to solderability issues and dewetting (where the coating may not be evenly spread across the surface).

One of the more recent trends in thermal paste is the use of carbon based fillers. The advantage of these is their excellent lubricity and ability to conform to the irregular surface of a CPU core. These fillers are typically derived from graphene, nano-tubes or carbon nano-fibers. Some manufacturers also incorporate a small amount of alumina into their thermal paste blends to provide both abrasion resistance and increased performance.

The HY 880 thermal compound from Arctic is a great example of this new trend. It comes with a stencil kit that allows for clean installation and a very precise amount of paste to be applied. The resulting thermal conductivity is good enough for mid-range to high-end PCs, though it’s certainly not suitable for the very best systems. You get ten 1 gram syringes of this product with the kit, which is a pretty decent amount for the price.