Advantages of Spiral Freezers

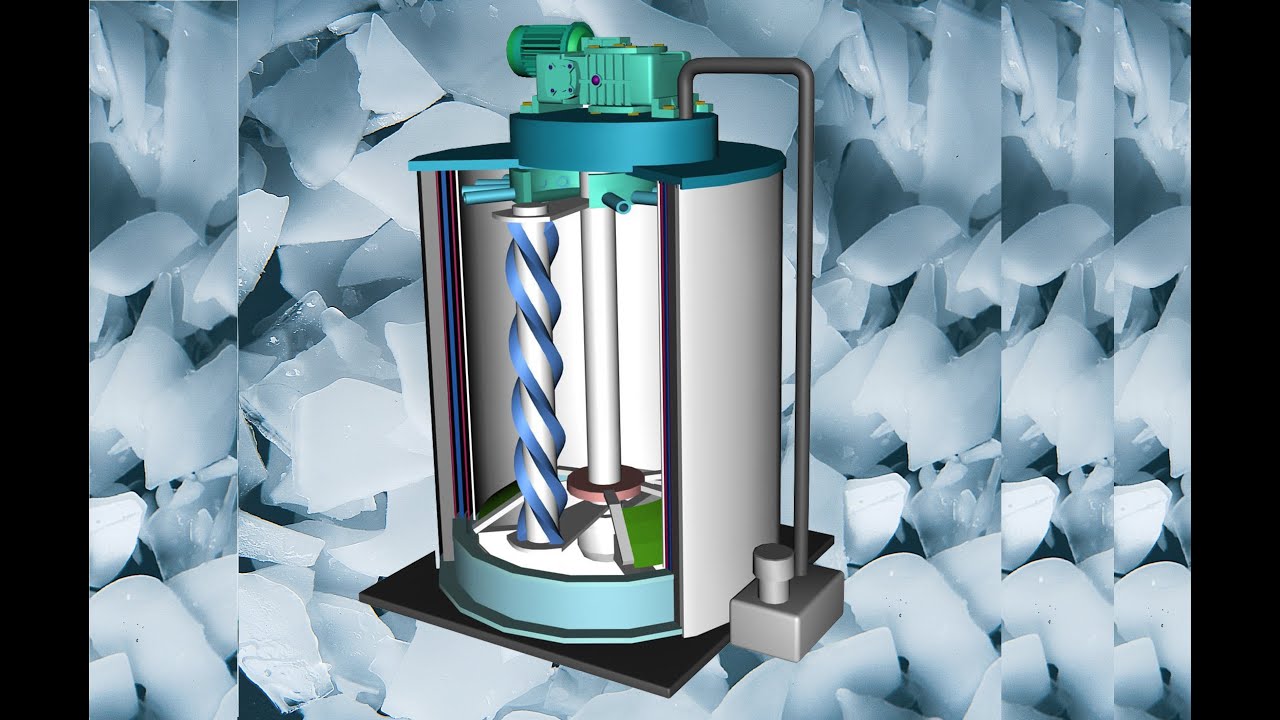

A spiral freezer is a mechanical freezing machine that mechanically transports packaged food products on a continuous conveyor belt through a tightly controlled cooling process to quickly decrease the product’s temperature. Spiral freezers offer several advantages over traditional freezer types, including faster freezing times and superior hygiene. This makes them the ideal freezer for food processing and packing companies that need to rapidly cool their products, as well as retail and wholesale packaging suppliers that need a fast and reliable solution for frozen food storage.

A major advantage of spiral freezers is that they operate with sterilized stainless steel holding trays that do not contact the food, and the freezing process is germ-free. This is especially important in food preparation, where hygienic conditions are critical. This ensures that the product is free from contamination and stays fresh, safe to consume, and that its quality is consistent throughout the entire freezer process. The high velocity of the cold airflow also ensures that each tier is exposed to the coldest temperatures for the longest period of time, which allows for quick and thorough freezing.

Spiral freezers are designed to achieve maximum energy efficiency, which helps reduce utility costs and operating expenses. They can be operated at a low temperature set point with lower fan speeds than conventional freezers, which can lead to significant savings in energy usage and cost. Additionally, spiral freezers can be integrated with existing refrigeration and process control systems to improve product quality, reducing manual intervention that pulls personnel away from other plant responsibilities.

Spiral Freezers offer many customizable features and options to meet your needs. The size and dimensions of your spiral freezer can be tailored to your specific operations, and manufacturers may even allow you to add an additional conveyor belt tier to maximize capacity. They can be used to chill, crust or full freeze a wide variety of foods and are built from durable, reliable stainless steel.

Most spiral freezers come with a range of temperature setting options, which are suitable for pre-freezing, freezing, and chilling foods. The freezer can be adjusted to different settings based on the needs of your business, and this flexibility helps maintain efficient cooling performance as production changes over time.

Another customizable option is the spiral freezer’s speed, which can be adjusted to suit your specific needs. This can be adjusted to allow for a higher production rate or to increase the energy efficiency of the system. This can be particularly useful during seasonal impacts to your facility, where the load of a spiral freezer may change significantly from one season to the next.

Spiral freezers use advanced evaporators to minimize product weight loss, which increases yield and production efficiency. They also feature a patented impingement design that delivers the coldest air to every product tier directly from the evaporator. This guarantees a rapid and uniform freeze, which saves energy and reduces product loss. In addition, a specialized vapor balance system minimizes air and moisture infiltration into the freezer to preserve cryogen gas for optimum freezer performance.